FAILURE ANALYSIS

Discover more about the services

FAILURE ANALYSIS PROCESS

The Failure Analysis is a critical process to determine how and why a product, or a component is not able to work in a correct way. The aim is to minimise or remove the risk of event repetition which caused the failure.

The Gestlabs laboratory offers the Failure Analysis service on printed boards, components and finished products.

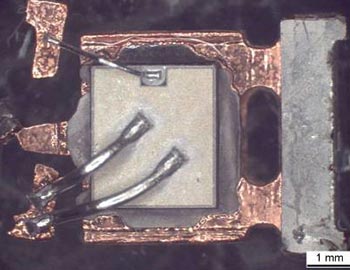

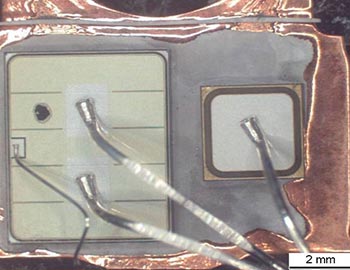

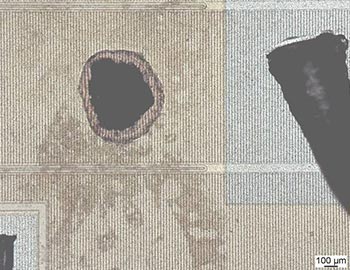

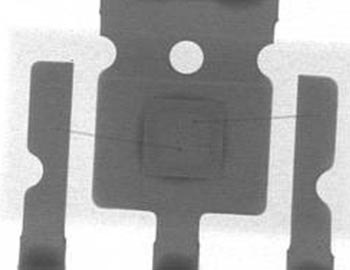

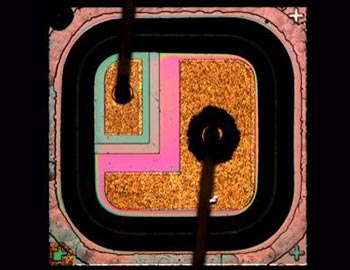

It uses the X-Ray analysis, C-SAAM and metallographic microsections for the component’s constructive analysis like MLCC, resistances and active components; datasheet electrical test for the characterisation of passive components like resistances, capacities, inductances, wirings and of the discrete active components like diodes, Mosfet, IGBT, Transistors. It is also able to perform the Decapsulation for the superficial analysis of dies and wire bonding.

For the Failure Analysis of PCB and PCBA, the Gestlabs lab can make the dimensional checks of conductors and of superficial insulations of printed boards; it can check the metallization and the stack-up through metallographic microsections and/or make the SEM-EDX electron microscopy analysis. Furthermore, it can check the compliance with IPC standards through X-Ray analysis and optical analysis.

Among the analytic techniques used in the failure analysis process, the Gestlab laboratory can use techniques like FT-IR (Fourier Transform InfraRed Spectroscopy) analysis for the organic compounds research, the electrical checks (voltage, continuity), the Dye & Pry, and the SEM-EDX electron microscopy analysis.

In the defectiveness analysis of the product, we can define the Failure Analysis path, to perform the analysis of stress condition of components due to the design, and to measure and perform the electrical characterisation at full capacity and during the transients.

We can perform the Failure Analysis of active and passive components, to make the infra-red heat map with measurements on components in the thermal camera, to simulate the failures, and to define the possible solutions.